Every NASCAR team brings its own playbook to Phoenix Raceway, where the statistics, setups, and split-second decisions can make or break a championship run. But since the advent of Next Gen cars in 2022, the sport’s tighter rulebook has left engineers walking a fine line, searching for every ounce of performance without crossing into forbidden territory.

Advertisement

At the asymmetric one-mile desert oval, where each corner demands a different braking and handling approach, car setup is always a balancing act. One of the few tricks still on the table is splitting brake pads, a high-risk but high-reward tactic that can tune handling through the turns.

While NASCAR teams can no longer design custom suspension or brake components, they still manipulate performance by mixing friction compounds and fitting different brake pads on each corner of the car.

This process, known as splitting brake pads, helps tailor braking behavior, making a car sharper or more stable under corner entry. Teams may split pads front-to-rear or side-to-side, using different friction materials to suit specific handling characteristics.

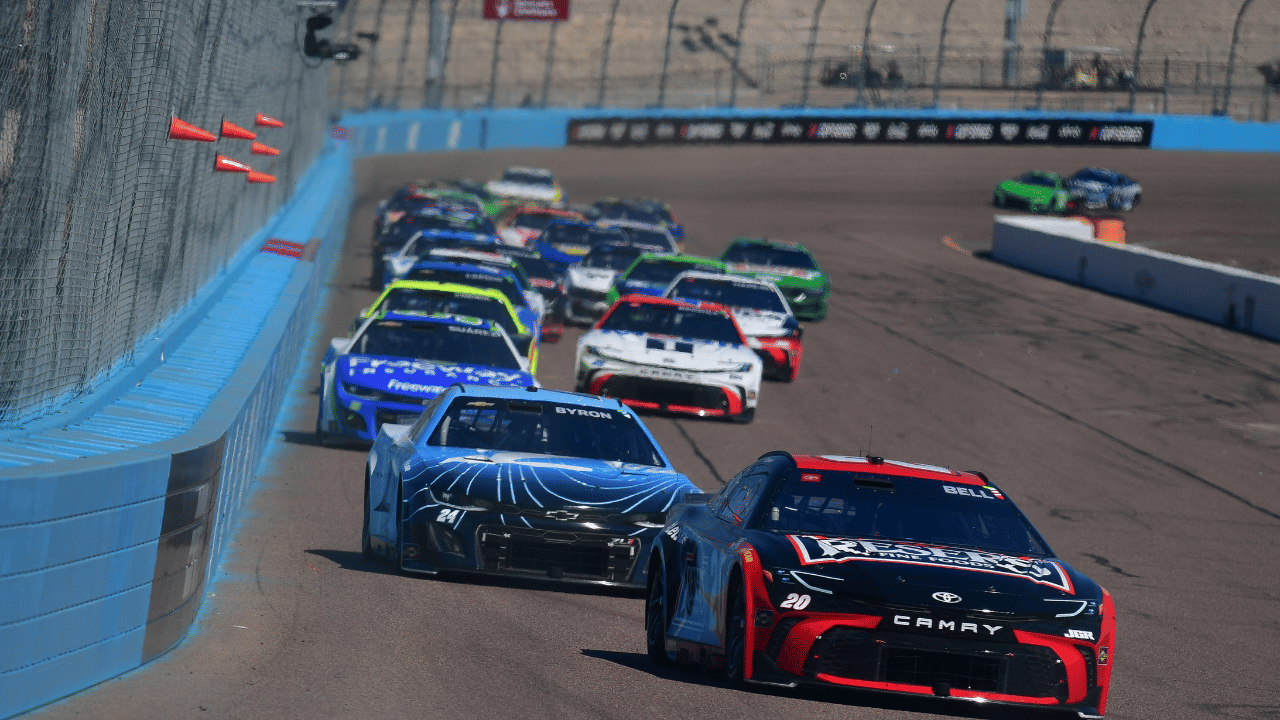

However, that edge comes at a price. Uneven friction can push brake temperatures to the limit, risking catastrophic failures. The danger became evident in the 2023 championship race at Phoenix, when Christopher Bell’s No. 20 Toyota Camry suffered a right-front rotor explosion caused by pad splitting, an incident that ended his title hopes on the spot.

Joey Cohen, president of GMS Race Cars, explained the method as a way to “tune for balance based on how braking torques are applied.”

The approach affects how weight transfers through the car under braking, controlling load on each corner, and optimizing temperature ranges. Teams experiment with setups, front versus rear, left versus right, or even one-corner adjustments, to prevent lockups when a wheel momentarily loses grip.

At Phoenix, where Turn one entry off the dogleg differs drastically from the straight-line approach into Turn 3, split brake pads can level out handling inconsistencies between corners. Combined with in-car brake bias controls that let drivers adjust front-to-rear pressure on the fly, the configuration helps equalize stability through the track’s contrasting turns.

Long straightaways at Phoenix also create huge temperature swings in the braking system. To counter overcooling on the straights, NASCAR teams sometimes modify the friction compounds on specific corners to maintain consistent heat levels.

Meanwhile, aerodynamics play a larger role at Phoenix than at most short tracks. Split pads can even help smooth out platform variations caused by aero load shifts, stabilizing the car’s posture at high speed.

Working around the rules has always been a part of NASCAR racing and teams have found ways to work around the Next Gen spec parts model.

One of those ways is to alter how a car handles by mixing up brake pads on purpose.

My latest story for @Motorsport: https://t.co/Gs61xZjDVN

— Bozi Tatarevic (@BoziTatarevic) October 29, 2025

Still, the gamble is very much real as overheated rotors can expand enough to touch the pads, only to cool rapidly on the straights, causing fractures or shattering. Then, splitting braking pads may lead to high-temperature compounds trapping residual heat, and may even damage caliper seals or crack rotors entirely, leading to corner failure.

For both the NASCAR teams, Hendrick Motorsports and Joe Gibbs Racing, chasing an edge at Phoenix, the challenge will lie in knowing when to push the limits and when to lift before innovation turns into implosion.